Partagez:

ABA Deux Couches Extrusion De Gonflage

Panier d'enquête

Détails du produit

ABA Blown Film Extrusion

Main Technical Variables :

| Model | ABA 1000 |

| Screw Diameter | Ф45×1 Ф55×1 |

| Screw Ratio L/D | 30:1 |

| Screw Speed | 15-120r/min |

| Main Motor Power | 15Kw×1 18.5KW×1 |

| Extrusion Output | 100kg/h |

| Range of Die | Ф100 |

| Single-sided Thickness of Film | 0.01-0.10mm |

| Max. Folding Width of Film | 800mm |

| Electric Total Capacity | 50Kw |

| Overall Dimension | 5000×3500×5000mm |

| Weight of Machine | 4T |

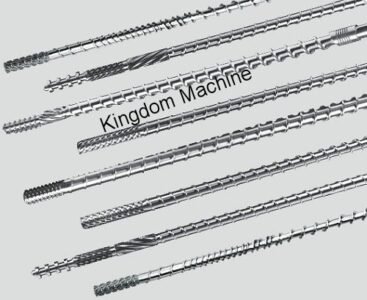

Extruder

Screw Dia. (mm): ф45×1 ф50×1

Screw & Barrel L/D Ratio: 30: 1

Barrel: 38 CRMOALA ALLOY

Barrel Heater Capacity (Kw): 10*3

Barrel Auto Thermo Control: 4 Points

Cooling Blower: 3kw

Driving Motor: 15Kw×2 (Siemens Motors with inverter type)

Screen Changer: manual type

Screen Changer Heater Capacity (Kw): 3

Dosing system

Gravimetric blender 2 (2 materials will or master batch will be mixed fixed % on each screw feeder),

Die:

Rotary die device

Die Dia. (mm): φ120

Die Heater Capacity (Kw): 10

Die Auto Thermo Control: 1 Point

Air Ring: 1 Set

Bubble Basket: Hexagon Type

Take-up Unit:

To be possible to moving the tower 2.2m

Pinch Roller- Embossing Roller

Take-up Motor with Inverter Control: AC: 1.5kw

Optional parts:

AUTO Winding Unit

EPC (Edge position control)

Hydraulic unloading device

Triangle folder

Slit and seal knife,

Automatic double winder,

Tension control system

Max. Width (mm): 1200

Max. Wind-up roll dia. (mm): φ 1000

Winding Motor: 2.2KW motor with inverter *2pc

with autotension control and inverter

Flat cutting knives and film opening knives

Air shfts= 4 pcs

Banana rollers = 2 pcs 2

Rewinding Speed: 10-80m/min